Product Name: 3-Way Diverting Control Valve

Main Structure: 2 Outlet, 1 Inlet

Key Features: Three Way, Diverting Type, Double Seat

Body Material: ASTM A217 WC9

Size: 2 Inch, DN50

Pressure: Class 150 LB, PN16

End Connection: Flanged

Actuation: Multi-spring Pneumatic Diaphragm Actuator

Seat Leakage: GB/T 4213 Class IV (Metal Seal)

Product Range

Body Material: ASTM A216 WCB, ASTM A217 WC9, ASTM A352 LCB, ASTM A351 CF8, CF3, CF8M, CF3M

Size Range: 3/4-12 Inch, DN20-DN300

Pressure Rating: PN16-PN100, Class 150-600 LB

End Connections: Flanged, Welded

Media: Water, Gas, Oil, Steam

Working Temperature: -196°C to +450°C

Flow Characteristics: Equal Percentage, Linear

Actuator Options: Pneumatic Actuators

Three-Way Control Valves-Features

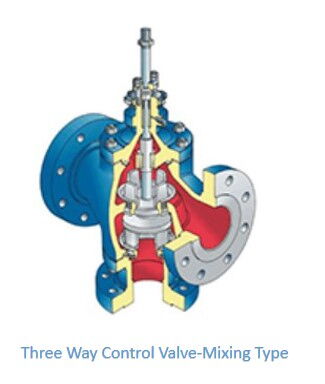

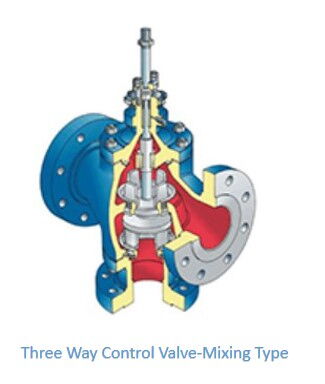

Three-Way Control Valves are versatile devices used to either divert a single fluid into two separate flows or mix two fluids into one. They provide precise control by adjusting the flow area between the plug and the valve seat.

1. Types and Functions

Mixing Control Valve: Combines two fluid streams into a single flow.

Diverting Control Valve: Directs one fluid stream into two separate outlets.

2. Operation

When the flow area between the plug and one valve seat increases, the flow area through the other seat decreases, allowing for accurate control over mixing or diverting processes.

3. Design Considerations

Unbalanced Plug Structure: Ideal for applications involving diverting or mixing but not suitable for high differential pressure conditions.

Temperature Sensitivity: Leakage may increase when fluids at different temperatures flow through the valve, due to differing expansion rates of the valve plug and seat. To minimize leakage, the temperature difference between the fluids should not exceed 150°C.