How to Effectively Address Noise Problem in Control Valves

On this page

In various industrial sectors, control valves play a crucial role in managing fluid flow and pressure to ensure the smooth operation of production systems. However, along with their functionality, control valves often come with a common yet challenging issue — noise. This noise can not only disrupt the tranquility of the work environment but also have adverse effects on the health of workers. Therefore, it is imperative to delve into the sources of noise in control valves to explore viable solutions.

Noise in control valves arises primarily from three aspects: self-vibration, aerodynamic, and fluid dynamic phenomena.

- Self-vibration-induced noise: The valve core of control valves may undergo abrasion due to the flow of the medium, leading to instability and vibration. This vibration, under specific conditions, can trigger resonance, resulting in significant noise. Even under normal operating conditions, the valve emits continuous yet slight vibrations, which contribute to a certain degree of noise.

- Aerodynamic noise: When the medium passes through the contraction section of the control valve, abrupt flow changes convert part of the fluid's mechanical energy into sound energy, generating aerodynamic noise. This noise typically stems from abrupt fluid flow changes and the turbulence and vortices generated during the flow.

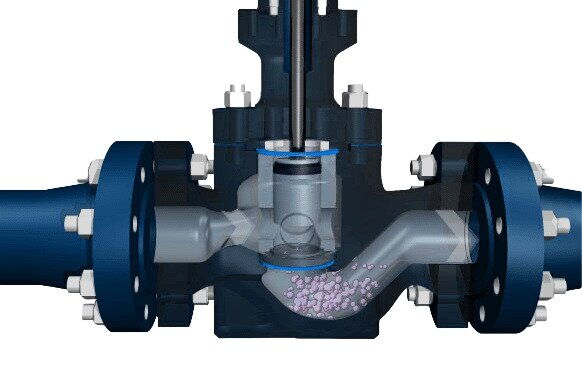

- Fluid dynamic noise: Excessive flow velocity or pressure differences during fluid passage through the control valve may lead to a phenomenon known as cavitation. Cavitation occurs when, under certain inlet conditions, the flow rate reaches its maximum as the downstream pressure gradually decreases. In such cases, fluid flow can induce flashing and erosion, resulting in intense noise.

To tackle the main noise issues during the regular operation of control valves, several common solutions can be implemented.

1. Resonance elimination: By adjusting valve structure design, optimizing materials, or incorporating vibration absorbers, resonance phenomena can be eliminated to prevent noise generation and amplification.

2. Cavitation noise reduction: Utilizing appropriate valve designs, fluid control techniques, or enhancing system stability can reduce cavitation occurrences and diminish noise sources.

3. Application of sound-absorbing materials: Installing sound-absorbing materials such as foam plastics or sound-absorbing panels around the noise source effectively absorbs noise and minimizes its propagation.

5. Using muffler: Adding series mufflers in control valve pipelines exploits their sound absorption properties to lower aerodynamic noise, effectively reducing noise levels.

6. Soundproofing enclosure: Constructing soundproof enclosures around control valves or using soundproofing materials to cover the noise source isolates it and reduces its impact on the surrounding environment.

In conclusion, resolving noise issues in control valves requires a comprehensive consideration of factors such as structural design, fluid control, and the application of sound-absorbing materials. By employing suitable solutions like resonance elimination, fluid control improvement, sound-absorbing materials, or soundproof enclosures, noise levels in control valves can be effectively reduced, creating a quieter and more comfortable working environment while safeguarding the health of workers.