Key Design Enhancements of Pneumatic Diaphragm Control Valves

On this page

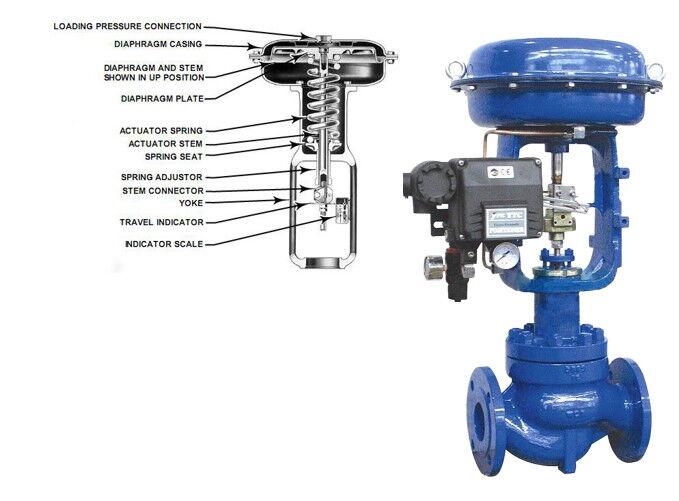

Pneumatic diaphragm control valves play a vital role in automation systems, regulating key parameters like flow, pressure, and temperature. These valves are indispensable in industrial operations. While the core performance aspects such as control accuracy and response speed are often emphasized, it's the details, components like the stem connectors, exhaust valves, and feedback rods that influence the control valve stability and long-term precision. Neglecting these details can lead to instability, poor regulation, and even production failures.

The stem connector is a crucial part of the pneumatic diaphragm control valve, ensuring its operation and control accuracy. Traditional stem connections are simple, but over time, or in specific operating conditions, they may suffer from looseness and stroke deviations, which affect stability and reliability. Here, we analyze common issues and their solutions.

Most pneumatic diaphragm valves use an external threaded stem connected to an internal threaded push rod. The stem screws into the push rod and is locked with two nuts. This design allows for easy adjustment of the stem stroke and preload. However, in long-term operations or systems prone to surge, the traditional double-nut lock may not secure the connection firmly. In high-pressure environments or steam-water systems, nuts can loosen, causing the stem to drop and leading to valve over-opening, resulting in process failures. Additionally, the threaded connection is cumbersome during maintenance, making disassembly and adjustment inefficient.

To address these shortcomings, some manufacturers have adopted forged threaded double-clamp mechanisms. This design includes anti-loosening features and offers greater connection strength, preventing stem loosening. One of its key advantages is ease of installation and maintenance. This innovative solution significantly enhances valve stability, particularly in high-pressure, high-temperature, or frequent-start-stop applications, ensuring longer service life and improved reliability.

Exhaust valve design is critical for the long-term stability and performance of pneumatic diaphragm control valves, especially in outdoor environments. Improper design or handling of exhaust holes can lead to external factors like rain, dust, and gas leaks entering the diaphragm chamber, which accelerates diaphragm aging and damage. Below, we explore common exhaust valve issues and suggest improvements.

Pneumatic diaphragm control valves are often installed outdoors, exposed to varying weather conditions. Poorly designed exhaust valves allow rain, dust, or harmful substances from leaks to enter the diaphragm chamber. This not only speeds up diaphragm wear but can also cause rusting of springs, bolt corrosion, and other failures. These issues significantly affect valve stability and shorten its service life. In particular, exhaust hole design is vital for direct-acting actuators. Some manufacturers, aiming for component compatibility, use the same upper and lower diaphragm covers for both direct and reverse-acting actuators, leading to poor exhaust hole handling.

Most valves today use plastic exhaust caps or simple air-source connectors, which lack durability and water-splash protection. We recommend installing silencers to treat exhaust holes. Silencers facilitate smooth gas flow, reduce noise, and effectively block dust and liquid from entering, enhancing the protective function. This simple, cost-effective solution improves valve durability and reliability, reducing diaphragm damage and internal corrosion, thus improving overall stability.

Feedback rods play an essential role in the operation of pneumatic diaphragm control valves. They transmit the valve's position to the positioner, enabling precise adjustments to valve openings and maintaining flow, pressure, and temperature within set limits. The design of the feedback rod directly influences control accuracy and system stability. Optimizing feedback rod design is key to improving regulation precision and reducing hysteresis.

The feedback rod is crucial for transmitting the valve's position to the positioner. The positioner adjusts the actuator based on the feedback signal to precisely control the valve opening. Whether using a force-balance positioner or an intelligent positioner with an electronic feedback device, the feedback rod must reliably relay the valve's position to ensure the control system can adjust as required. Thus, the feedback rod's design is vital for control accuracy and system stability.

To enhance control accuracy, attention must be given to the feedback rod design. Key optimization areas include:

The connection between the push rod and feedback device must be stable and balanced to avoid problems like hysteresis caused by loose or poor connections.

The precision of the feedback rod's engagement with the positioner is critical. Poor alignment can lead to inaccurate feedback, affecting valve regulation and response speed.

Additionally, the feedback rod material should be durable and resistant to corrosion, especially in high-temperature, high-pressure, or corrosive environments. It must also be resistant to fatigue and wear. By optimizing feedback rod design and improving its compatibility with the positioner, hysteresis can be minimized, ensuring precise flow control under various conditions.

The performance of pneumatic diaphragm control valves depends not only on core components like diaphragms, actuators, and control systems but also on details such as stem connectors, exhaust valves, and feedback rods. Ignoring these design elements can lead to instability, reduced control accuracy, and system failure. Therefore, designers and manufacturers must pay more attention to optimizing each component to ensure accuracy and stability. By adopting advanced connection structures (e.g., forged threaded double-clamp mechanisms), improving exhaust hole design (e.g., using silencers), and optimizing feedback rod design (enhancing feedback accuracy), the performance, service life, and reliability of pneumatic diaphragm control valves can be significantly improved. As industrial automation and intelligence continue to advance, optimizing these design details will be key to enhancing overall performance and reliability.