Key Factors in Selecting Pneumatic Diaphragm Control Valves

On this page

Pneumatic diaphragm control valves are widely used in various industrial production processes due to their simple structure, convenient operation, high reliability, and fire and explosion-proof characteristics, especially in the production process of alumina. Selecting the appropriate pneumatic diaphragm control valve requires a comprehensive consideration of multiple factors, including safety, flow characteristics, valve size, and usage requirements. Here is a detailed explanation:

Safety is the primary consideration when selecting a pneumatic diaphragm control valve. There are two basic types of pneumatic diaphragm control valves: fail-open and fail-closed valves. The choice should be based on the safety requirements of the production process and usage requirements.

When the signal pressure is interrupted, the valve opens automatically. It is suitable for situations where the interruption of the signal has a minimal impact on the process, such as when the continued flow of the fluid does not significantly affect the system. Fail-open valves are commonly used in applications that require continuous flow or to prevent system shutdown.

When the signal pressure is interrupted, the valve closes automatically. It is suitable for situations where closing the valve can prevent significant harm to the production process when the signal is interrupted. For example, it is used in systems where immediate cessation of fluid flow is necessary to prevent accidents or damage.

Choosing the appropriate valve type based on process requirements and the impact of signal interruption on production can maximize safety and reduce potential risks.

The flow characteristics of a pneumatic diaphragm control valve determine its control performance. Different flow characteristics are suitable for different process requirements, mainly including the following.

The flow is directly proportional to the valve opening. With the same change in valve opening, the change in flow is larger at low flow rates and smaller at high flow rates. This characteristic is suitable for systems with relatively stable load changes but is not suitable for situations with drastic load changes, as it may cause oscillation at small openings.

The relationship between flow and opening is logarithmic. This characteristic has a weaker control effect at low loads and a stronger control effect at high loads. It provides good control performance and is suitable for applications with large load changes, such as feed regulation in reactors or evaporators.

The flow changes rapidly when the valve is close to fully open, suitable for situations that require quick on/off of flow. This characteristic is commonly used for gas flow control and applications that require rapid start/stop.

The flow is related to the valve opening in a parabolic relationship. It is suitable for applications that require specific flow control and can provide stable flow regulation over different opening ranges.

Choosing the appropriate flow characteristic can improve the control accuracy and stability of the system, meeting the needs under different process conditions.

The selection of the valve size is crucial for the flow control of the system. The choice of size should be based on the flow coefficient (CV) of the fluid. The flow coefficient CV is a key parameter for measuring the flow capacity of the valve, which needs to consider the type of fluid (liquid, gas, steam, etc.) and working conditions.

The liquid flow coefficient depends on the viscosity and density of the fluid. The appropriate CV value should be determined based on the flow requirements, fluid properties, and system pressure loss.

The calculation of the gas flow coefficient is more complex, requiring consideration of the compressibility and temperature effects of the gas. Generally, the CV value for gases is larger because the flow resistance of gases is relatively small.

Choosing the appropriate size can ensure that the valve effectively controls the flow during operation and ensures the efficient operation of the system.

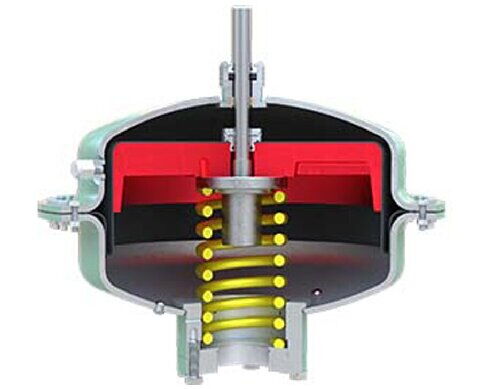

The pneumatic diaphragm control valve consists of two parts: the valve core and the valve body (including the seat). The structural form of the valve varies according to different usage requirements.

Determines the flow characteristic and control precision of the valve. The design of the valve core should consider the type of medium, flow range, and pressure conditions to achieve the best control effect.

Affects the durability and adaptability of the valve. Different materials and structural forms of the valve body are suitable for different working environments, such as high temperature, high pressure, or corrosive media processing.

Choosing the appropriate valve core and valve body structure according to specific process requirements and working environments can improve the reliability and service life of the valve.

When selecting a pneumatic diaphragm control valve, it is necessary to consider safety, flow characteristics, valve size, and usage requirements comprehensively. By choosing the valve form and parameters reasonably, the production process can be optimized, the stability and control accuracy of the system can be improved, and the safety and efficient operation of production can be ensured. The correct choice not only helps to improve production efficiency but also effectively avoids potential operational risks, ensuring the smooth operation of the process system.