Pneumatic Control Valve Failures: Common Issues and Solutions

On this page

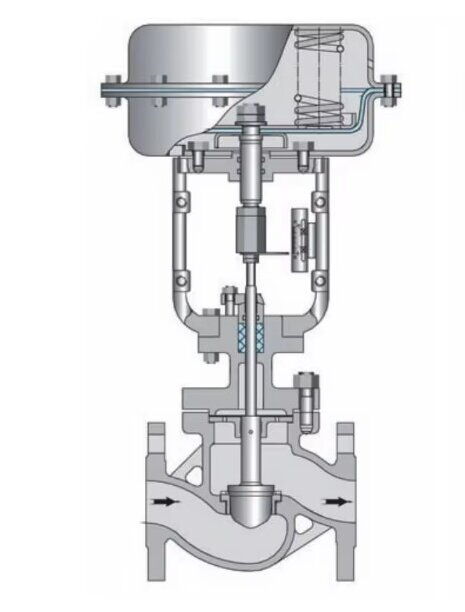

Pneumatic control valves play a crucial role in industrial automation systems and find extensive applications in industries such as petroleum, chemical, and power generation. Due to their complex operating environments and frequent operational demands, pneumatic control valves often encounter various faults. This article provides a comprehensive overview of common faults in pneumatic control valves, their causes, and solutions to help maintenance personnel troubleshoot effectively and enhance system reliability and stability.

Valve body failures are among the most common issues encountered during the use of pneumatic control valves. Such failures can lead to improper valve operation, affecting the stability of the entire system. Below are common valve body failures and their solutions.

Butterfly Valve Issues: Metal seat damage in butterfly valves can cause the valve body to jam. Detachment of fixed pins or stripped bolts connecting the ball valve core to the valve stem can result in the valve shaft moving without affecting the valve core.

Ball Valve Issues: Internal wear in ball valves can lead to valve jamming or sluggish movement. Damaged soft sealing gaskets may cause internal leaks or blockages.

Segmented Ball Valve Issues: Damage to the valve stem sleeve in segmented ball valves can make valve operation difficult.

Steam Valve Issues: Steam valve stem seals can leak due to high-temperature aging, and the dislodgment of silencers can cause valve jamming and excessive noise.

Valve Stem Issues: Wear or corrosion of the valve stem can lead to internal leaks. Damaged seals at the packing area can also result in leaks.

Leakage at the Valve Core and Seat: Caused by surface wear or corrosion, inadequate actuator force, or loose valve seat threads. Solutions include improving the grinding of mating surfaces, adjusting actuator and valve stem connections, and tightening or replacing valve core seats.

Leakage Between the Seat Ring and Valve Body: Caused by insufficient tightening torque, poor surface finish of the valve body, inappropriate gaskets, or small holes or burrs in the valve body. Solutions include increasing tightening force, cleaning and processing the valve body, replacing gaskets, or re-welding the valve body.

Packing Leakage: Caused by poor surface finish or bending of the valve stem, insufficient or incorrect packing cover pressure, excessive packing height, packing corrosion, or deformation of the packing gland. Solutions involve polishing and straightening the valve stem, re-tightening or replacing packing, installing spacer rings, reducing packing height, using higher-quality packing materials, and repairing or replacing the packing gland and related flange bolts.

Valve Stem Vibration: Caused by disconnection or breaking of the stem connection, often due to excessive torque or improper pin connections. Solutions include using integral valve core-stem components or welding the valve core, ensuring secure connections, and eliminating vibration sources.

The cylinder is a crucial component of the pneumatic control valve's actuator. Cylinder failures can directly impact the valve's operation. Below are common cylinder failures, their causes, and solutions.

Limit Bolt Displacement: Leads to air leaks in the cylinder, resulting in valve movement issues or failure to reach the desired opening position.

O-Ring Damage: Causes air leaks, making valve operation difficult or impossible.

Piston Deformation: Results in increased friction, and loose cylinder bolts can cause air leaks, leading to operational difficulties.

Linkage Mechanism Loosening or Rusting: Causes difficulties in valve movement.

Insufficient Cylinder Capacity or Spring Faults: Leads to valve operation issues.

Piston Seal Leakage: Caused by poor cylinder finish, inadequate piston ring sealing, or damage due to excessive temperature or prolonged use. Solutions include polishing the cylinder, adjusting limit bolts, selecting seals based on temperature, and ensuring proper installation.

Loose Limit Bolts: Solutions involve re-tightening the bolts.

Increased Piston Friction: Solutions include reapplying lubrication, cleaning and polishing the cylinder and piston.

Difficulty in Valve Movement: Caused by insufficient or damaged actuator springs or incorrect position of limit blocks. Solutions include calibration, re-adjustment, or replacing springs.

The positioner is a key component in pneumatic control valve systems, converting control signals into the valve's actual position. Failures in positioners can lead to abnormal valve movements, affecting control precision. Below are common positioner failures, their causes, and solutions.

Circuit Board Faults: Lead to abnormal valve movements.

Small Valve Faults: Damage or wear can cause abnormal valve movements, primarily due to poor instrument air cleanliness or foreign objects entering the positioner.

Proportional Valve Failures: Result in abnormal valve movements.

Sliding Rheostat Failures: Lead to inaccurate valve positioning, often due to high environmental temperatures or liquid ingress.

Broken O-Ring at Air Source Interface: Causes jamming of the small valve stem.

Poor Gland Head Sealing: Results in water ingress damaging the circuit board.

Environmental Factors: Excessive pipeline vibration, high temperatures, or high humidity can lead to circuit board faults.

Gland Head Sealing Issues: Lead to water ingress and circuit board damage. Solutions include improving gland head sealing to prevent internal water ingress.

Poor Instrument Air Quality: Causes foreign objects to damage small valves. Solutions include adding air filters to improve air quality.

Temperature and Humidity Issues: Lead to frequent damage of sliding rheostats and circuit boards. Solutions involve separating circuit boards from small valves and rheostats, creating a modular positioner design.

Broken O-Rings: Caused by excessive air source pressure. Solutions include maintaining air source pressure around 0.4 MPa and using high-quality sealing rings.

The process and design of pneumatic control valves play a vital role in their performance and reliability. Inadequate design or changes in process parameters can lead to valve failures. Below are common faults due to process and design issues and their solutions:

Changes in Process Parameters: Lead to excessive pipeline pressure differentials, causing valve movement issues.

Scaling Due to Medium: Causes abnormal valve movement.

Pipeline Blockages: Prevent normal valve operation.

Design Selection Issues: Result in insufficient actuator capacity, inadequate torque, or valve body material incompatibility.

Excessive Pressure Differential: Prevents normal valve opening. Solutions include installing bypass valves before and after the control valve.

Scaling in Valve Body: Prevents normal valve opening. Solutions include adding flush water pipes, regularly cleaning the valve, and polishing the valve core if necessary.

Pipeline Blockages: Prevent normal valve operation. Solutions involve optimizing operational procedures, preventing pipeline blockages, and flushing the valve.

Design Selection Issues: Solutions include optimizing process parameters during the design phase to ensure accurate selection and avoid issues.

Pneumatic components are crucial for the normal operation of pneumatic control valves. Damage to these components can lead to abnormal valve movements, affecting system performance. Below are common faults due to pneumatic component damage and their solutions:

Aging Air Source Hoses: Damage or leaks in air source hoses or stainless steel air source pipes can cause low air source pressure, leading to abnormal valve operation.

Air Filter Damage: Dirty or damaged filter elements can cause abnormal valve operation.

Low or Unavailable Air Source Pressure: Leads to abnormal valve operation.

Damage to Air Source Hoses or Filters: Solutions include replacing with high-quality air source hoses or air filters and performing regular inspections.

Low Air Source Pressure: Solutions include adjusting air source pressure to meet the minimum requirements of the pneumatic valve.

In conclusion, through in-depth analysis and implementation of appropriate solutions for valve body, cylinder, positioner, process, design, and pneumatic component failures, we can effectively prevent and address common faults, enhancing system reliability and operational stability. Regular maintenance and design optimization not only reduce failure rates but also ensure the long-term efficient operation of pneumatic control valves, providing robust support and assurance for industrial production.