Principles and Applications of Electric Control Valves

On this page

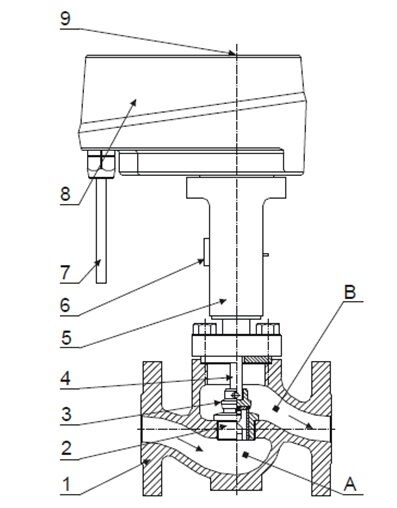

The electric control valve serves as an intelligent control device, regulating the flow, pressure, temperature, and other parameters of a fluid by controlling the opening and closing of the valve through an electric actuator. Widely employed across industries such as chemical, petroleum, metallurgy, and power generation, the electric control valve stands as a crucial equipment for fluid transmission control.

Electric control valves are sophisticated devices designed to regulate the flow, pressure, temperature, and other parameters of fluids within industrial processes. They operate based on the principle of utilizing electric actuators to modulate the opening and closing of the valve, thereby controlling the flow rate of the fluid. Below are the key principles and features that define electric control valves.

1. Precision Control

Employing modern control technologies, electric control valves achieve high-precision adjustments of fluid parameters with a control accuracy of up to ±1%. Compared to traditional manual control valves, electric control valves excel in precision control.

2. Intelligent Operation

Featuring intuitive interfaces, electric control valves offer simplified operation and can be remotely controlled via computers, smartphones, and other terminals, facilitating real-time monitoring. This operational method not only enhances operational efficiency but also reduces manual intervention, mitigating risks associated with human error.

3. High Safety and Stability

Often equipped with sealing structures, electric control valves effectively prevent safety incidents caused by fluid leakage. Additionally, their simple and stable structures enable them to withstand high working pressures, ensuring prolonged stable operation.

4. Long Service Life

Incorporating advanced actuation mechanisms and intricate components such as coaxial components, temperature sensors, and electronic control systems, electric control valves demand high precision and quality for each part, thereby ensuring a longer service life.

5. Environmental Protection and Energy Efficiency

Electric control valves boast excellent energy-saving performance, reducing energy consumption and holding significant importance for energy conservation. Furthermore, they eliminate the need for hydraulic oil, thereby preventing emissions of exhaust gases and residues, and minimizing environmental pollution.

Electric control valves find extensive applications in various sectors, including but not limited to.

- Oil and Gas Industry: Employed in pipeline systems to regulate the flow of oil and gas, ensuring smooth transportation.

- Chemical and Petrochemical Production Processes: Utilized to regulate the flow and pressure of liquid media in chemical production, ensuring process stability and safety.

- Non-Ferrous Metal Smelting: Utilized for controlling parameters such as temperature and pressure during smelting processes, guaranteeing production quality and equipment safety.

- Synthetic Fiber Production Processes: Used for controlling the flow of liquid media in fiber production, ensuring uniformity and quality.

In these sectors, electric control valves offer precise flow control, the ability to handle high-pressure and corrosive media, advanced remote control, accurate positioning, and rapid response, making them indispensable. Their significance in industrial production continues to grow, contributing significantly to enhancing production efficiency and ensuring product quality.