Principles of Mechanical Limit Adjustment for Electric Actuators

On this page

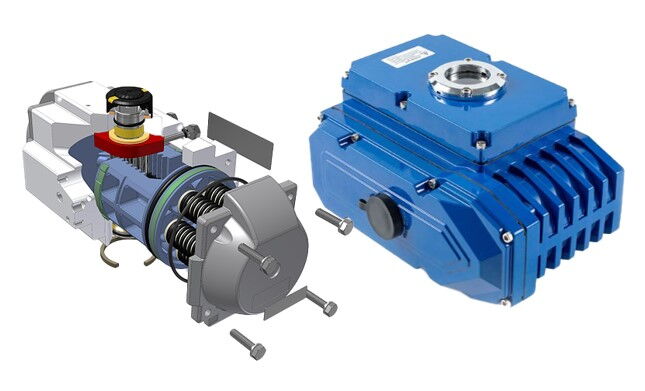

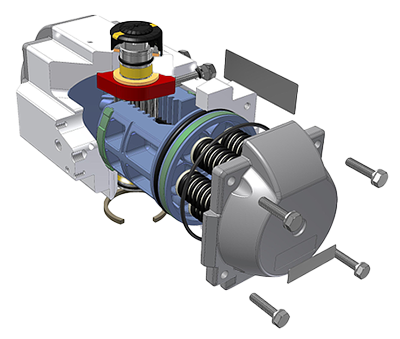

Mechanical limit adjustments are essential for ensuring the proper functioning of electric actuators in modern industrial automation. These adjustments play a key role in controlling and regulating valves, enhancing system efficiency and operational safety. Although electric actuators are typically set with mechanical limit screws during production, further adjustments may be necessary in specific scenarios. This article outlines the principles of mechanical limit adjustment for electric actuators, detailing the steps involved, types of switches, detection methods, and important installation precautions.

Before performing mechanical limit adjustments on electric actuators, it’s crucial to understand and adhere to these fundamental principles.

Determine the specific valve positions that the limit screws will restrict. For instance, when the valve closes by turning to the right, the right side is designated as the closed limit screw, while the left side is the open limit screw. Proper identification of these limit screws ensures that the valve operates safely within its intended range.

During the adjustment process, it’s important to avoid excessive changes to the limit screws. Over-adjustment can cause the valve to exceed its designed opening range, potentially disrupting normal system operation. For example, excessive adjustments may prevent the valve from fully closing, resulting in fluid leaks or system malfunctions.

Before making any adjustments, ensure that the power to the electric actuator is turned off. Implement necessary safety measures, such as wearing personal protective equipment, to minimize the risk of accidents.

Following effective steps for mechanical limit adjustment is vital for ensuring the electric actuator operates correctly. Here are the detailed steps to follow.

First, adjust the valve to the desired limit position based on process requirements. This ensures that the valve can achieve the necessary flow or pressure during operation.

Rotate the limit screws until they make contact with the actuator's mechanism, ensuring that the valve stops at the predetermined position. Adjust the returning limit screw by 0.5 to 1 full turn to establish the travel limit and provide safety protection against over-torque. This step helps prevent damage to the valve when it reaches its limit.

After completing the adjustments, loosen the locking nut on the limit screw and then tighten it. Ensure that the limit screw is securely fixed to prevent it from loosening during operation.

Once the switches and mechanical limits are confirmed, perform multiple open-and-close operations on the valve to ensure proper functionality. The following detection methods can be employed:

For switch-type actuators, adjust the valve to both fully open and fully closed positions, then use a hand controller to set the actuator. Verify that the valve operates correctly at both extreme positions.

For regulating-type actuators, provide a 4 to 20 mA current via the Distributed Control System (DCS) controller to confirm that the valve can reach both fully closed and fully open states. Check the settings in the secondary setup menu to ensure that the valve's opening matches process requirements across all operational states.

Electric actuators are critical components in automation control systems, allowing for precise fluid flow control. Their main functions include:

Electric actuators can accurately adjust the flow, pressure, and temperature of fluids, accommodating various process requirements. They are commonly used in industries such as chemical processing, oil and gas, and power generation.

By automating control, electric actuators reduce the need for manual intervention, enhancing production efficiency and operational safety. Their effective operation contributes to increased overall productivity while lowering operational costs.

Proper mechanical limit adjustments ensure that equipment operates within safe parameters, preventing damage or accidents caused by excessive switching or adjustments. Safety measures help reduce failure rates and extend the lifespan of equipment.

When installing and debugging electric actuators, adhere to the following precautions.

Ensure that the electric valve actuator is installed correctly. Check that all mechanical connections and electrical wiring comply with standard requirements. Both power and control circuits must be connected properly to avoid operational failures.

Before limit adjustment, verify that the manual device of the actuator is functional and set to manual mode for control. This allows for quick responses during debugging.

Utilize the manual handle to adjust the valve's opening and closing angles until the desired limit position is reached. Once confirmed, switch the manual device back to automatic mode to complete the limit adjustment.

Access the actuator controller's settings interface, select the "Limit Adjustment" option, and set the opening and closing limit angles as needed. After completing the adjustments, save the settings and exit the adjustment mode to ensure they take effect.

Mechanical limit adjustment for electric actuators is a vital step to ensure proper valve operation. By identifying limit positions, adhering to adjustment procedures, checking switch types, and following safety protocols, users can effectively master mechanical limit adjustments for electric actuators. Maintaining equipment in good condition enhances production efficiency and ensures safety in the manufacturing process. With a solid understanding of these principles, operators can better manage the maintenance and adjustment of electric actuators, achieving efficient and safe industrial automation.