Uncover Bellows Sealed Control Valve for Demanding Applications

On this page

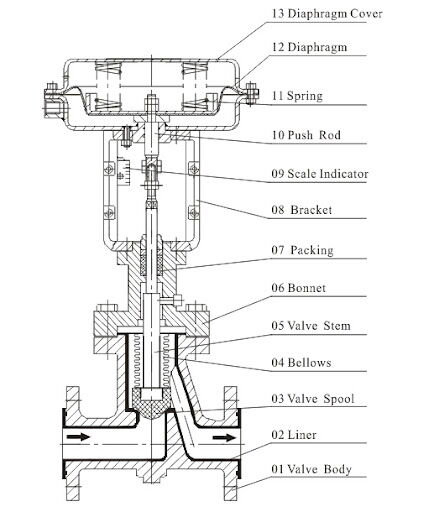

The pneumatic bellows sealed control valve is a high-performance control valve that combines the advantages of a multi-spring pneumatic diaphragm actuator and a bellows-sealed control valve body. It is specifically designed to address issues caused by high differential pressure and low flow rates, making it ideal for applications requiring precise control of flow and pressure. Its unique bellows design excels in handling toxic, flammable, explosive, and valuable media, ensuring the safety and stability of the system.

The bellows sealed control valve operates by receiving signals from the control system, utilizing either electric or pneumatic actuators to drive the bellows adjustment mechanism, thus altering the valve opening. This change influences the flow and pressure of the medium, achieving the desired control of process parameters.

The bellows are a key component of the control valve, characterized by their high elasticity and plasticity, allowing them to adapt to various medium flow changes. When the medium flows in from the inlet, the internal pressure on the bellows causes deformation. This deformation is translated by the actuator into control signals for adjusting the valve opening.

The bellows sealed control valve achieves precise control of medium flow by adjusting the valve opening. When the flow increases, the bellows deformation increases, prompting the actuator to reduce the valve opening. Conversely, when the flow decreases, the bellows deformation decreases, and the actuator increases the valve opening. This dynamic balance allows the bellows sealed control valve to maintain a stable flow output.

Similarly, the valve can regulate medium pressure by adjusting the valve opening. When the pressure rises, the bellows deformation increases, and the actuator reduces the valve opening to lower the pressure. Conversely, when the pressure drops, the bellows deformation decreases, and the actuator increases the valve opening to raise the pressure.

The bellows-sealed sleeve pneumatic control valve employs sleeve guidance and a pressure-balanced valve core design, suitable for high differential pressure conditions. Its main features include:

Sleeve Guidance: Provides stable guiding performance, reducing friction and wear, thereby extending the valve’s lifespan.

Pressure-Balanced Valve Core: Utilizes a balanced sealing ring instead of the traditional double-seat sleeve valve structure, converting it into a single-seat sleeve structure, significantly enhancing the valve’s sealing performance.

Dual Sealing: Incorporates both bellows and packing seals in the valve cover, completely eliminating the possibility of medium leakage, making it especially suitable for controlling the flow and pressure of toxic or valuable media.

Under conditions of high differential pressure and low flow rates, the pneumatic bellows sealed control valve needs to address several challenges.

Ensuring the actuator has sufficient output force to handle high differential pressures. The actuator design must consider the additional load under high differential pressure to guarantee stability and reliability.

Ensuring the strength of components to withstand high pressure. The high-pressure environment demands higher material and structural standards for valve components, necessitating the use of high-strength, corrosion-resistant materials.

Ensuring sealing performance under high pressure. High-pressure seals require special design to prevent medium leakage and ensure system safety.

Selecting suitable materials and fine processing techniques to improve durability and sealing performance. The valve core and seat are critical components, and their material and processing quality directly impact the valve’s lifespan and performance.

Bellows sealed control valves are widely used in the following scenarios.

Toxic Media: Such as chlorine gas and ammonia gas, which pose significant hazards to the environment and personnel, requiring excellent sealing performance.

Flammable and Explosive Media: Such as natural gas and liquefied petroleum gas, which can easily cause fires and explosions if leaked.

Valuable Media: Including various rare gases and liquids, which are expensive and require zero leakage during use.

Corrosive Media: Such as various acid and alkali solutions, requiring strong corrosion-resistant materials.

In conclusion, the pneumatic bellows sealed control valve, with its efficient flow and pressure control capabilities, excellent sealing performance, and structural features that adapt to various harsh conditions, is an indispensable device in industrial processes. Whether handling toxic, flammable media or operating in high differential pressure environments, the bellows sealed control valve provides reliable solutions to ensure the efficient and safe operation of the system.