What's the Use of Positioners in Control Valves

On this page

In modern industrial automation control systems, valve positioners play a critical role. As essential accessories for control valves, their function extends beyond mere valve actuation. Through precise feedback and adjustment mechanisms, valve positioners ensure that control valves accurately respond to the controller's output signals, thereby maintaining the system's efficiency and stability. This article will delve into the working principles of valve positioners and their specific applications in various scenarios.

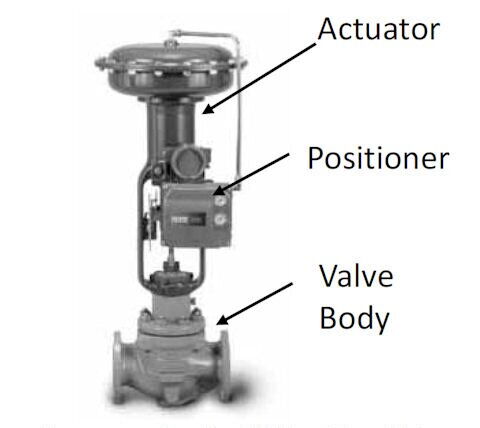

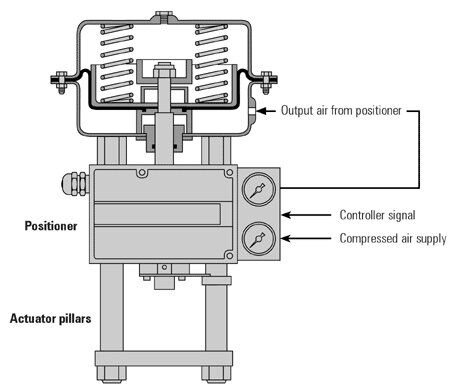

A valve positioner is a key accessory for control valves. Its primary function is to use the valve stem displacement signal as a feedback measurement signal and the controller's output signal as a setpoint. When there is a deviation between these two signals, the valve positioner alters the output signal to drive the actuator, thereby establishing a one-to-one correspondence between the valve stem displacement and the controller's output signal. Thus, the valve positioner forms a feedback control system where the valve stem displacement is the measurement signal and the controller output is the setpoint.

Valve positioners significantly enhance the performance of control valves in industrial automation systems by ensuring accurate response to control signals through feedback and adjustment mechanisms. Here are some of the key roles they play.

1. Improving Regulation Quality and Reliability: Valve positioners greatly enhance the positioning accuracy and reliability of control valves, making them suitable for critical control systems that demand high regulation quality. Precise valve position control achieves more stable process control, reduces fluctuations, and improves overall system performance.

2. Overcoming Pressure Differential Issues: In situations where there is a significant pressure difference across the valve, valve positioners increase the actuator's output force by boosting the air supply pressure. This helps counteract the unbalanced force exerted by the fluid on the valve plug, reducing stroke error and ensuring stable operation under high-pressure conditions.

3. Preventing Leakage: For media that are high-temperature, high-pressure, toxic, flammable, or explosive, tight packing is often required to prevent leakage, leading to significant friction between the valve stem and the packing. Valve positioners can overcome this friction-induced delay, ensuring timely valve response.

4. Overcoming Media Resistance: In environments with viscous fluids or media containing solid suspensions, valve positioners effectively counteract the resistance to valve stem movement, ensuring smooth valve operation and enhancing system reliability.

5. Increasing Thrust: For large-diameter control valves, valve positioners can increase the actuator's output thrust, ensuring proper valve operation under various conditions, which is particularly important in large-scale industrial installations.

6. Improving Response Speed: When the distance between the controller and the actuator exceeds 60 meters, signal transmission may experience delays. Valve positioners adjust the signal transmission path and method, effectively overcoming these delays and significantly improving the valve's response speed and the system's dynamic performance.

7. Enhancing Flow Characteristics: Valve positioners can optimize the flow characteristics of control valves, making flow changes more linear across different valve openings. This improves the control precision and stability of the system.

8. Achieving Split-Range Control: When one controller is used to control two actuators, two valve positioners can be employed to receive low and high input signals separately. This allows one actuator to operate at a low range and the other at a high range, achieving split-range control. This approach enables more complex control strategies and increases the system's flexibility and adaptability.

In summary, valve positioners play a vital role in industrial automation systems. With their various advantages, they provide robust support for the stable operation and efficient control of these systems. Understanding and correctly applying valve positioners not only enhance the performance of control systems but also ensure the safe and efficient operation of industrial processes.