A Comprehensive Guide to Control Valve Types and Applications

Control valves play a crucial role in engineering, and the correct selection of the appropriate valve type is key to ensuring the normal operation of systems. In light of the classification and characteristics of control valves, let's delve into the features and suitable applications of different types of control valves to make informed decisions in practical engineering.

1. Straight-Through Single Seat Control Valve

Straight-through single-seat control valves feature a simple structure and excellent sealing, suitable for clean media with strict leakage requirements and low differential pressures. Although small-sized control valves can be used in applications with high differential pressures, it's not advisable to use them in situations with high-pressure differentials and large diameters, as special attention is needed to prevent them from being lifted open.

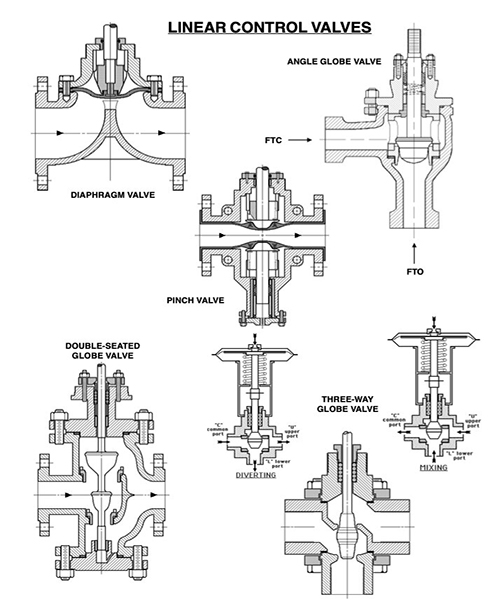

2. Straight-Through Double Seat Control Valve

Straight-through double-seat control valves offer good sealing and allow for larger pressure differentials, making them suitable for high-pressure differential situations with high flow rate requirements. Compared to single-seat control valves, they have higher flow capacities but may pose issues with higher leakage rates.

3. Sleeve Type Control Valve

Sleeve type control valves, employing a valve core and cage structure, boast excellent stability and easy maintenance, making them suitable for reducing noise and cavitation effects. However, they come at a relatively higher price and are unsuitable for controlling unclean media or media prone to crystallization and scaling.

4. Angle Control Valve

Angle control valves are specialized single-seat control valves suitable for specific piping and fluid scenarios, featuring excellent self-cleaning properties. They are suitable for scenarios with unclean media and media containing suspended particles. Additionally, they can be further improved into anti-blocking angle valves, ideal for situations with suspended particle-laden media, especially in cases of limited installation space.

5. Three Way Control Valve

Three-way control valves utilize the valve core's self-guidance and can be used for diverting and merging two flow groups and for temperature differentials ≤150℃. When using them, it's crucial to understand the meaning of "gas open" and "gas closed" to determine whether they should be positioned horizontally or vertically.

6. Diaphragm Control Valve

Diaphragm control valves, composed of a corrosion-resistant diaphragm and a valve body lined with corrosion-resistant material, are suitable for two-position cut-off situations involving unclean media and mildly corrosive media. However, due to poor regulating quality and constraints from operating conditions, their application scenarios have relatively diminished.

7. Butterfly Valve

Butterfly valves act as a section of the pipeline with a throttling valve plate in the center, suitable for low-pressure, medium-pressure, or high-flow scenarios. They have a small size and light weight, being 4 to 10 times lighter than ball-type control valves of the same diameter, making them especially suitable for large-diameter applications. However, butterfly valves have pressure limitations, with a relatively narrow application range.

8. Ball Valve

Ball valves are a type of control valve with a simple flow path, low flow resistance, and minimal losses, suitable for high-flow and unclean media scenarios. Different types of ball valves have their own characteristics, allowing for the selection of appropriate models based on specific requirements. For instance, O-type ball valves are suitable for high-flow and unclean media scenarios, while "V" type ball valves are suitable for high-viscosity, suspended flow, pulp, and other unclean media containing fibers.

9. Eccentric Rotary Valve

Eccentric rotary valves combine the advantages of ball valves and butterfly valves, suitable for scenarios involving crystallization, clogging, and unclean media. They offer excellent regulating performance, stable operation, and, when paired with a positioner during proportional control, achieve better regulating effects.

In conclusion, different types of control valves have their own characteristics, suitable for different operating scenarios. When making selections, it's essential to consider specific engineering requirements, media properties, and system operating conditions comprehensively to ensure the selection of the most suitable valve type, safeguarding the stability and safety of system operation.