Managing Common Control Valve Leakages

In modern automated control systems within factories, control valves play a pivotal role as terminal execution devices, receiving control signals and regulating chemical processes. However, due to prolonged usage and environmental factors, various leakage problems often occur, compromising their safety and performance. This article aims to provide a detailed analysis of common leakage problems encountered with control valves, along with proposed solutions, to assist engineers in better maintaining and managing these critical components.

1. Internal Leakage

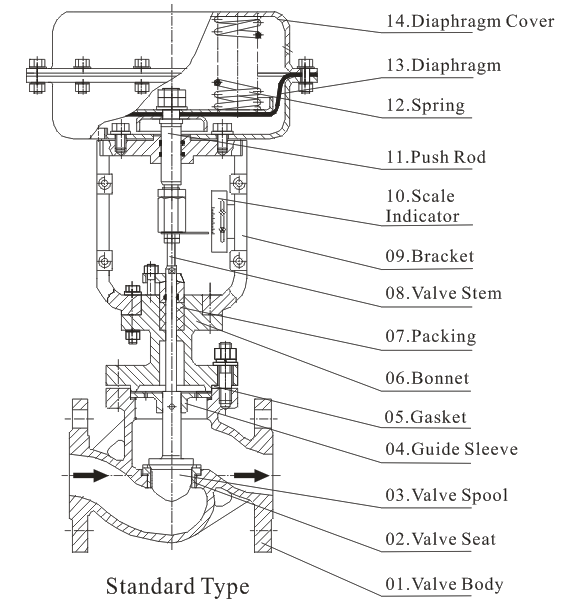

Internal leakage represents one of the most prevalent faults in control valves, primarily attributed to improper stem length or wear of valve cores and seats. When the stem is either too long or too short, inadequate contact between the valve core and seat occurs, resulting in internal leakage. Moreover, prolonged usage leads to wear of the valve core and seat, further impairing sealing performance. The solution involves adjusting stem length or replacing valve cores and seats to ensure complete valve closure and eliminate internal leakage.

2. Packing Leakage

Packing leakage is another common issue, often arising from uneven contact between packing and stem or aging of the packing material. Upon packing insertion into the stuffing box, the plasticity of the packing generates radial force. However, uneven contact between the packing and stem leads to leakage. Additionally, prolonged usage causes packing material aging, diminishing its sealing capabilities. Solutions include adjusting stuffing box design, selecting suitable packing materials, and periodically replacing aged packing to ensure proper sealing between the packing and stem.

3. Valve Core and Seat Deformation Leakage

Deformation leakage of valve cores and seats typically results from manufacturing defects or corrosion from the medium. Corrosive media induce deformation of valve cores and seats, compromising their sealing integrity and causing leakage. Furthermore, prolonged exposure to high temperatures and pressures exacerbates deformation. To address this, it's crucial to select corrosion-resistant materials, eliminate product defects, and replace valves when necessary.

In conclusion, leakage problems in control valves significantly impact the efficiency of automated control systems within factories. Therefore, proactive detection and resolution of these issues are essential for ensuring their safe operation and stable performance. Regular maintenance and upkeep of control valves are equally vital for prolonging their lifespan and enhancing production efficiency.