A Quick Understanding of Control Valves

On this page

Control valves play a crucial role in industrial automation systems, helping manage things like pressure, temperature, and liquid levels. In this article, we'll break down how control valves function and explore the many places they're used, showing just how vital they are in keeping modern industries ticking along smoothly.

Control valves find wide-ranging applications across industries including manufacturing, engineering, and scientific fields. Their primary function is to adjust fluid flow rates, thereby influencing process properties such as pressure, temperature, and liquid level. By employing control valves, precise control over these parameters is achieved, ensuring process stability and reliability.

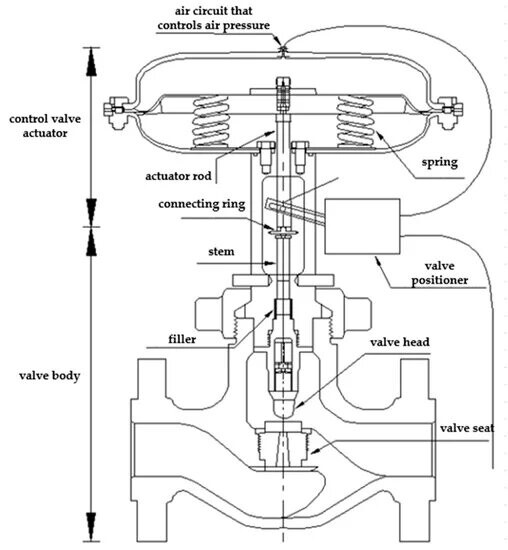

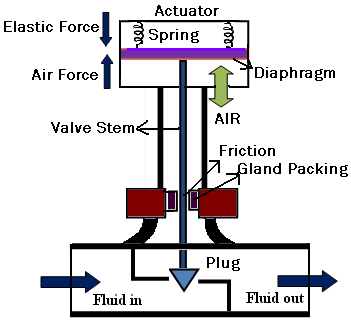

The operation of control valves is based on forming a closed-loop control system. A controller sends signals to the control valve, which adjusts the valve's opening accordingly, altering fluid flow rates. Typically, control valves utilize actuators to move the valve stem, which can be pneumatic or electric. Fluid flow rates are dependent on the valve's opening and the pressure differential between the inlet and outlet.

Control valves find extensive applications across various industries. In pipeline systems, they are used to regulate fluid flow, ensuring the stable operation of the system. In the oil and gas industry, control valves control fluid pressure and flow rates, ensuring operational safety and efficiency. In food and beverage production, control valves adjust fluid temperature and concentration, ensuring product quality and taste. In the biopharmaceutical industry, control valves regulate material flow in reactors, ensuring precise process control. In the marine industry, control valves regulate fluid flow on ships and offshore platforms, ensuring the safe operation of equipment.

Control valves are indispensable components of modern industrial automation systems, playing a crucial role in achieving precise control over fluid flow rates. By regulating fluid flow, control valves influence process properties, ensuring process stability and reliability. As industrial technology continues to advance, the application scope of control valves will expand further, providing reliable support for the development of various industries.