Control Valve Flow Characteristics and Their Practical Applications

On this page

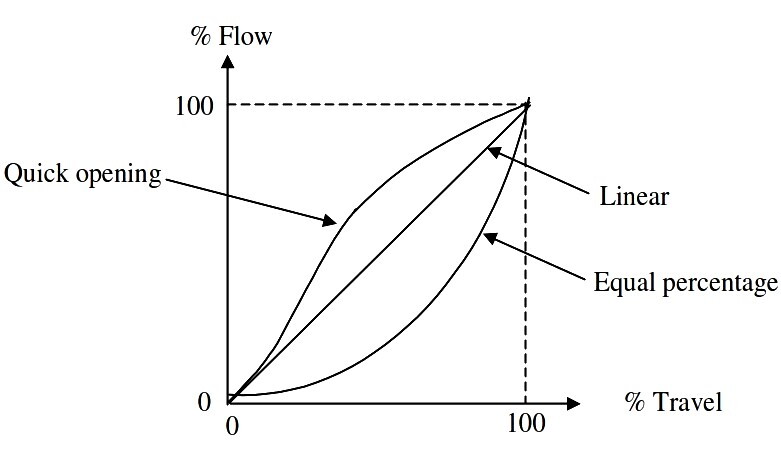

Control valves are crucial components in industrial control systems, and their flow characteristics profoundly influence system stability and control efficiency. Commonly encountered flow characteristics of control valves include linear, quick-opening, and equal percentage characteristics, each serving distinct purposes in various applications.

Linear flow characteristics establish a direct correlation between the relative flow rate and the relative valve opening of a control valve. Put simply, a constant change in relative stroke results in a consistent alteration in relative flow rate. While this characteristic is straightforward and intuitive, it presents challenges in practical scenarios. Notably, at low openings, significant flow rate variation occurs, leading to system oscillations. Conversely, at high openings, the flow rate variation is relatively small, resulting in sluggish response and poor adaptability.

Quick-opening flow characteristics feature a swift increase in flow rate to its maximum value as the valve stroke is initially adjusted. This characteristic is prevalent in systems requiring rapid response, such as on-off and program control systems. Its advantage lies in its swift response capability, although it may lead to over-adjustment or instability in certain circumstances.

Equal percentage flow characteristics ensure relatively stable operation across the entire valve stroke range, with the percentage change in flow rate per unit stroke remaining constant. Particularly at high openings, significant amplification and sensitivity are observed, making it widely applicable. Its advantages include stability and flexibility, although some control precision may be compromised.

In practical applications, variations in the inlet and outlet pressures of control valves give rise to what is known as operating flow characteristics, representing the relationship between relative flow rate and relative valve opening. When control valves are in series with pipelines, changes in valve opening result in variations in flow rate and system resistance, causing distortion of flow characteristics. Conversely, when control valves are in parallel with pipelines, although the flow characteristics of the control valve remain unchanged, the adjustable range of the system is reduced, and in severe cases, control may be lost altogether.

To achieve control, control valves adjust their openings to change flow rates, which in turn affect the pressure drop at the inlet and outlet of the control valve. Thus, the actual flow characteristics of a control valve depend on the curve representing the relationship between flow rate and valve opening. In theory, system stability requires constant system gain, but in practical applications, system gain often varies. Therefore, selecting the appropriate flow characteristics of control valves aims to compensate for nonlinear system gains, necessitating complex theoretical analysis and calculations.

In summary, the selection of control valve flow characteristics needs to consider system requirements and factors such as pressure drop variations in practical applications, ensuring system stability and control effectiveness.