Comparing Pneumatic Ball and Butterfly Control Valves

On this page

In industrial pipeline systems, control valves play a crucial role in controlling the flow of fluids and ensuring the efficiency and safety of the entire system. Pneumatic ball control valves and pneumatic butterfly control valves are two common types of control valves, each with its own unique advantages and limitations. To help readers gain a deeper understanding of these two types of control valves, this article will explore them from multiple perspectives.

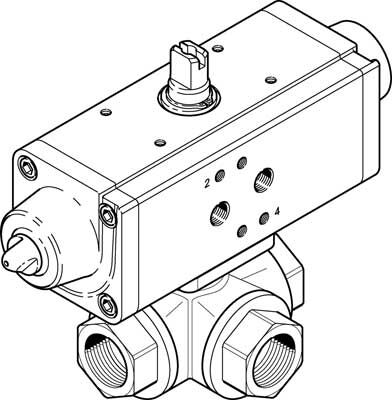

Pneumatic ball control valve is a type of valve controlled by a pneumatic actuator, operating by rotating the ball around the axis of the valve stem 90° to open and close. Widely used in industrial pipelines, this control valve is employed for cutting off, distributing, and altering the flow direction of fluids. Its main components include the ball, seat, and stem, enabling fluid flow control by managing the rotational movement of the ball.

Low Fluid Resistance: The alignment of the sphere with the pipeline results in minimal resistance when fluids pass through the valve.

Compact Design: The valve is ingeniously designed with a small volume and light weight, facilitating easy installation and maintenance.

Strong Sealing Performance: High-quality sealing materials such as polytetrafluoroethylene (PTFE) ensure the valve's sealing integrity.

Easy Operation: A simple 90° rotation is all that is needed to open or close the valve, making it suitable for automated control.

Low Maintenance Cost: Due to its simple structure, maintenance and part replacement are relatively easy.

Reliable Sealing in Fully Open and Closed Positions: The sealing surfaces of the sphere and seat are isolated from the medium, preventing medium erosion.

Wide Range of Applications: Capable of adapting to various diameters and pressure ranges to meet diverse industrial needs.

High Safety: Powered by gas, even if leakage occurs, it will not cause environmental pollution.

Limited Regulating Performance: Compared to other types of valves, the flow regulation capability of pneumatic ball control valves is weaker.

Temperature Limitations: The main sealing material has a lower temperature resistance, limiting its application in high-temperature environments.

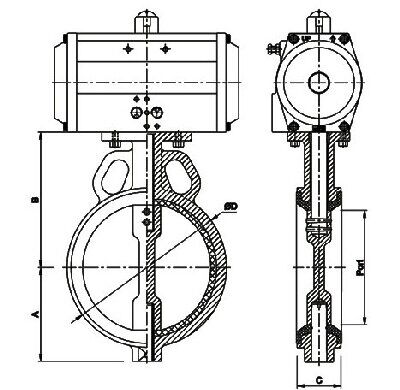

A pneumatic butterfly control valve consists of a disc-shaped closure member, a valve stem, and a valve seat. The rotation of the disc allows the valve to open and close, with a simple structure and convenient operation.

Quick and Easy Opening and Closing: The rotation of the disc makes the valve's operation effortless, reducing operation time.

Simplified Structure: Small in volume and light in weight, making it easy to install and transport.

Suitable for Slurries: The design of the butterfly valve minimizes the accumulation of liquid at the pipeline outlet, suitable for media such as slurries.

Good Low-Pressure Sealing Performance: It can maintain good sealing even under low-pressure conditions.

Excellent Regulating Performance: The disc of the butterfly valve can be adjusted to control the flow precisely.

Relatively Weak Sealing Performance: Compared to pneumatic ball control valves, the sealing performance of butterfly control valves may be less stable.

Not Suitable for High-Temperature and High-Pressure: There are significant limitations on operating temperature and pressure, making it unsuitable for extreme conditions.

Limited Regulation Range: The flexibility of flow regulation is not as good as other types of control valves.

When selecting a valve, it is necessary to decide based on the specific application scenario and requirements. Pneumatic ball control valves, with their high sealing performance and large flow capacity, are more suitable for industries such as oil, natural gas, chemical, power, and food and beverage. Pneumatic butterfly control valves, due to their small size and light weight, are more suitable for situations with space constraints or the need for lightweight applications, such as water treatment, HVAC systems, pharmaceuticals, papermaking, and textiles.

Pneumatic ball control valves and pneumatic butterfly control valves each have their strengths and play a key role in different industrial applications. Understanding their structural features, working principles, advantages and disadvantages, and application scenarios can help engineers and technical personnel make more suitable choices to ensure the efficiency and safety of pipeline systems. With careful design and reasonable configuration, both types of control valves can achieve the greatest benefits in their respective fields.