The Principle and Key Features of Cage Guided Control Valves

On this page

The cage guided control valve is a key fluid control device that precisely regulates the fluid flow by actuating the movement of the valve plug. Whether in the high-pressure differential environment of industrial processes or in complex processes requiring precise flow control, cage guided control valves offer unique design advantages and high efficiency capabilities. This paper will deeply study the working principle and main functional characteristics of cage guided control valve, reveal its important role in industrial automation control and application advantages.

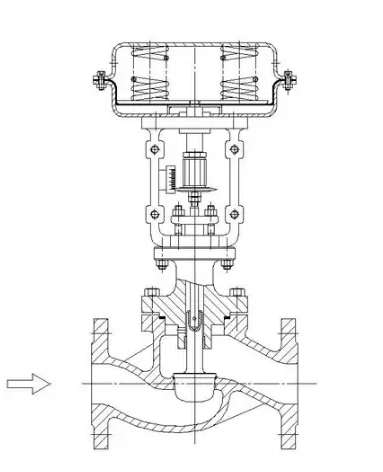

The cage guided control valve provides precise control of the fluid flow through the actuator's driving force. When the pneumatic or electric actuator receives the control signal, the stem rotates, thus changing the position of the valve plug. The change in the position of the valve plug regulates the area of the fluid channel and thus the flow of the fluid. The valve plug is usually a cage guide structure, which effectively reduces fluid shock and noise, while improving the stability of the regulation.

Cage guided control valve is widely used in various industrial fields because of its superior design and high performance. Its unique cage guide structure design not only improves the operation stability of the valve, but also has a variety of functional characteristics, so that it can operate stably under complex conditions. The following are the main functional characteristics of the cage guide control valve.

The cage guided control valve can realize the precise control of fluid flow and meet the adjustment needs of various complex working conditions. The fluid flow can be precisely regulated by changing the position of the valve plug by receiving the control signal through the electric actuator. Using advanced control algorithms and precision sensors, high-precision flow control can meet the requirements of various complex industrial processes. The advanced control system enables the valve to accurately respond to the control signal and achieve accurate flow control.

The cage guided control valve has a stable structure and is not easily affected by environmental factors such as pressure and temperature, which ensures the stable operation of the valve. The valve body and plug are made of high temperature and corrosion resistant materials to ensure long-term stable operation under harsh conditions.

Due to its structural characteristics, the cage guided control valve has a strong resistance to erosion and wear, so it has a long service life. The cage guide structure of the valve plug effectively reduces the impact of fluid on the valve body, reduces wear and prolongs the service life of the valve.

Cage guided control valve is a pressure balance control valve, its internal parts use sleeve guided pilot valve plug, mainly using fluid pressure to achieve rapid movement of the valve plug with minimal operating force. This design not only improves the response speed of the valve, but also reduces the operating load of the actuator.

The sealing type adopts single seat sealing, and the flow characteristic curve is highly accurate. The high performance sealing ring effectively improves the leakage level of the valve and ensures good sealing performance even under high and differential pressure conditions.

The control valve has good dynamic stability, low noise and anti-cavitation, and is suitable for controlling high-pressure differential fluids at various temperatures. The cage guide structure of the valve plug effectively reduces fluid noise and prevents cavitation.

Equipped with multi-spring diaphragm actuator or electric actuator, compact structure, large output force. This design not only improves the control accuracy of the valve, but also makes the installation and maintenance of the valve more convenient.

The fluid channel of the valve body is S-shaped streamline, the pressure drop loss is minimal, the flow rate is large, and the adjustable range is wide. The streamlined S-shape design reduces fluid resistance, increases flow, and improves the overall efficiency of the control valve.

The valve plug adopts cage guide structure to effectively reduce fluid shock and noise and enhance regulation stability. This design not only improves the performance of the valve, but also reduces industrial noise pollution.

It is mainly composed of regulating mechanism, valve parts and mechanical parts, with reasonable design, simple structure and easy maintenance and repair. Modular design makes valve disassembly and maintenance more convenient.

With its unique design and excellent performance, cage guided control valve can achieve accurate flow control under various complex conditions. Stable structure, strong durability, good sealing performance, suitable for a variety of industrial application scenarios. No matter in high pressure differential, high temperature, or harsh environment, keep the cage guided control valve can maintain excellent performance and stable operation, providing a reliable guarantee for industrial processes.