Explore Electric Butterfly Control Valves in Modern Applications

In modern industrial production and daily life, the regulation and control of flow within pipeline systems are of paramount importance. Electric butterfly control valves, as a common and critical flow regulation device, are widely utilized across various fields due to their efficiency, reliability, and ease of operation. These valves not only serve as shut-off valves, control valves, and check valves within pipeline systems but also play an irreplaceable role in enhancing production efficiency and ensuring system safety. This article will provide a detailed overview of the working principles, main functions, advantages, and broad application areas of electric butterfly control valves.

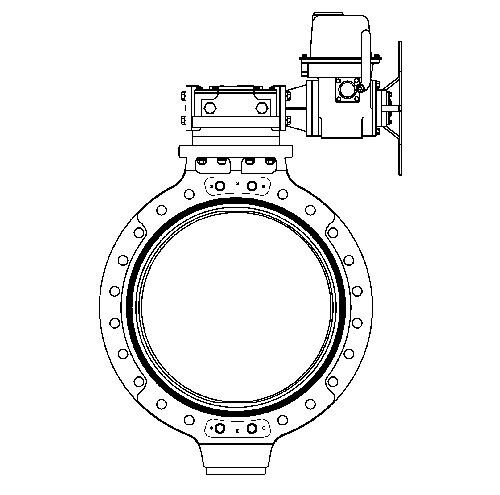

1. Working Principles of Electric Butterfly Control Valves

The working principle of an electric butterfly control valve involves using electrical energy as the driving force to control the opening and closing of the valve by adjusting the connection between the electric actuator and the valve stem. The electric actuator drives the hard-sealed butterfly valve disc to perform a partial rotational motion of 0 to 90 degrees. By receiving a 4-20mA signal from an industrial automation control system, the electric butterfly control valve precisely controls the valve's opening degree, thereby regulating and controlling various process parameters such as flow, temperature, and pressure.

Specifically, the electric actuator receives control signals to rotate the valve stem, which in turn drives the butterfly disc to rotate within the valve body. When the disc is perpendicular to the direction of fluid flow, the valve is closed; when it is parallel, the valve is fully open. By adjusting the angle of the disc, the flow rate of the fluid medium can be accurately controlled.

2. Main Functions of Electric Butterfly Control Valves

Electric butterfly control valves serve several main functions in industrial applications, primarily focusing on fluid control and system protection. Here are the main functions of electric butterfly control valves.

Controlling Fluid Medium Flow and Pressure: One of the primary functions of electric butterfly control valves is to regulate the flow and pressure of the fluid medium. By adjusting the valve's opening, operators can precisely control the flow rate and pressure to meet production requirements. These valves find extensive use in water treatment, wastewater treatment, food processing, chemical production, and petrochemical industries.

Protecting Pipeline Systems: Electric butterfly control valves contribute to protecting pipeline systems by effectively managing fluid flow. They help prevent leakage and loss of the fluid medium, control direction and flow rates, and maintain optimal pressure levels. This protection is crucial in avoiding equipment failures and ensuring overall system safety.

3. Advantages of Electric Butterfly Control Valves

Electric butterfly control valves offer several advantages that contribute to their widespread adoption in modern industrial and pipeline systems.

High Efficiency and Energy Savings: These valves feature a simple structure, compact size, and lightweight design, enabling efficient operation with minimal energy consumption. Compared to manual and pneumatic valves, electric butterfly control valves provide more precise control over flow rates and are suitable for large-diameter applications.

Easy Maintenance: The design of electric butterfly control valves facilitates straightforward maintenance, with key components easily accessible for inspection, repair, or replacement. The electric actuators are known for their durability and reliability, reducing downtime and maintenance costs.

High Degree of Automation: Modern electric butterfly control valves support remote monitoring and control through advanced automation systems. They can integrate with industrial control networks, allowing for adaptive control strategies, intelligent diagnostics, and fault self-diagnosis. This automation enhances production efficiency and operational safety significantly.

4. Applications of Electric Butterfly Control Valves

With ongoing technological advancements, electric butterfly control valves continue to evolve, expanding their applications across various industries:

Municipal Engineering: These valves are essential in municipal water supply and sewage systems, where they regulate water flow and pressure, ensuring efficient operation and reliability of water treatment plants.

Metallurgical Industry: In metallurgical processes, electric butterfly control valves are critical for managing high-temperature and high-pressure fluids in cooling water and steam systems, supporting the safety and stability of steel production operations.

Energy and Power Sector: Power plants utilize electric butterfly control valves in cooling water and fuel supply systems to control fluid flow and maintain operational efficiency and safety.

In conclusion, electric butterfly control valves play a pivotal role as automation control devices in fluid medium control and pipeline system protection. Their technological advancements continue to drive their adoption in diverse industrial sectors, supporting efficient and safe production processes.