Guidelines for Selecting Control Valve Flow Characteristics

On this page

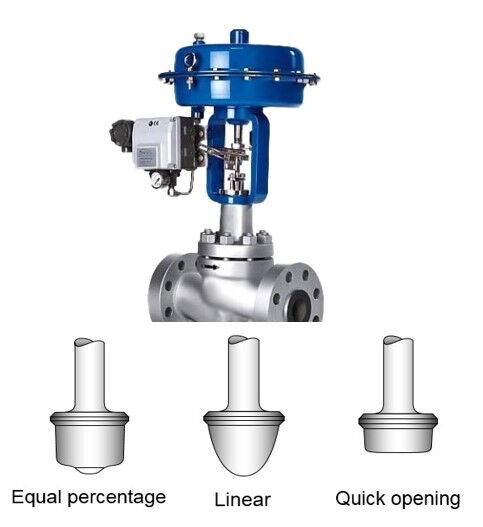

Control valves play a critical role in industrial control systems, and their flow characteristics directly impact the system's control performance and stability. Selecting the right flow characteristic for a control valve can significantly enhance the system's regulation accuracy and response speed. This article explores the primary flow characteristics of control valves—linear, equal percentage, parabolic, and quick opening—and provides specific selection criteria and principles to assist engineers in making informed decisions in practical applications.

The flow characteristics of control valves have a direct impact on the performance and stability of control systems. Below are the specific selection criteria for linear, equal percentage, parabolic, and quick opening control valves, which can help engineers choose the appropriate flow characteristic based on practical needs.

Control valves with linear characteristics exhibit a direct linear relationship between flow rate and valve opening. Specifically, as the valve opens, the flow rate increases linearly. This characteristic provides substantial flow changes at small openings but may offer less effective control at larger openings. Linear characteristic valves are suitable for applications with small load variations and constant pressure drops but are less appropriate for applications with low pressure drops or significant load changes.

Control valves with equal percentage characteristics show a logarithmic relationship between flow rate and valve opening. Each unit change in valve opening results in a percentage change in flow rate. These valves work smoothly when nearly closed and offer high sensitivity with large flow magnification near full open positions. Equal percentage characteristic valves are ideal for applications with significant load variations, especially where pipeline resistance is high or where there are substantial pressure differences before and after the valve.

Control valves with parabolic characteristics exhibit a flow rate variation between linear and equal percentage characteristics. The flow rate changes are stable at small openings and become smoother at larger openings. This characteristic is typically used in applications where a consistent flow change is needed across different valve openings.

Control valves with quick opening characteristics have a large flow rate at small stroke positions and rapidly reach maximum flow as the stroke increases. This feature makes them particularly suitable for position control and program control applications requiring rapid response.

Understanding the specific selection criteria for different flow characteristics is essential for choosing the right control valve. The following principles will guide engineers in making sound choices, thereby enhancing system control and stability.

To achieve optimal control performance, the open-loop gain and the product of gains in various loops should remain constant. Selecting an appropriate control valve flow characteristic can compensate for changes in the object's gain by adjusting the valve's gain, thus maintaining a consistent total gain in the system. This compensation principle is crucial for ensuring system stability and response speed.

The flow characteristics of a control valve are closely related to the pressure drop ratio of the pipeline system. Based on the pressure drop ratio, the suitable valve flow characteristics are:

Linear Characteristics: Suitable for situations with a constant pressure drop and small load variations. Due to instability at low flow rates and less effective control at large openings, these valves are not ideal for applications with low pressure drops or significant load changes.

Equal Percentage Characteristics: Suitable for high pipeline resistance or large pressure differences before and after the valve, especially when system loads vary significantly. These valves offer stable flow changes across various openings, making them highly adaptable.

Quick Opening Characteristics: Ideal for applications requiring rapid response, such as position and program control.

For control objects with self-balancing capabilities, equal percentage characteristic control valves are recommended as they maintain good control performance under significant load variations. For control objects lacking self-balancing capabilities, linear characteristic valves may be more suitable due to their stability under small load changes.

Equal Percentage Characteristics: Best for scenarios with high pipeline resistance or significant pressure differences before and after the valve, especially when system loads vary greatly.

Linear Characteristics: Suitable for constant pressure drops and small load variations, particularly in low flow situations where linear valves provide stable control.

Quick Opening Characteristics: Primarily used in position and program control applications, where rapid switching operations are required.

Selecting the appropriate control valve flow characteristic is crucial for ensuring stable and efficient system operation. By considering the system's pressure drop characteristics, load variations, and the control object's self-balancing capabilities, engineers can significantly enhance system performance and stability. Each flow characteristic has its unique applications and advantages, so it is essential to carefully assess the system's specific needs and operating conditions to achieve the best control outcomes.