Choosing Between Fail-Open and Fail-Close Control Valves

On this page

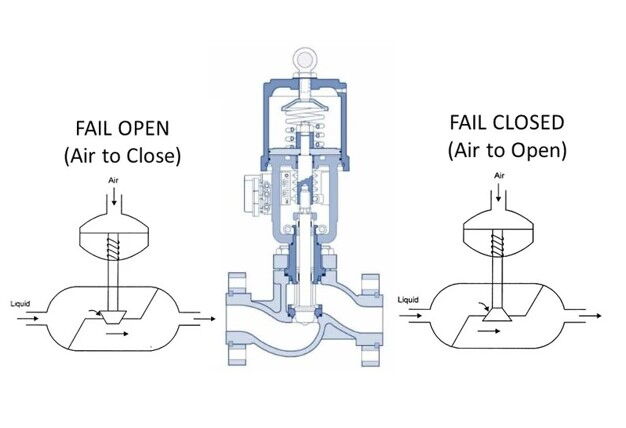

Control valves play a crucial role in industrial automation and process control. The mode of operation—fail-open (valve fully opens upon energy loss) or fail-close (valve fully closes upon energy loss)—directly impacts the safety and efficiency of the process. Proper selection of the control valve's fail-safe mode is essential for system safety and productivity. This article provides a detailed analysis of the criteria for choosing between fail-open and fail-close control valves.

Control valves typically operate in one of two primary modes: fail-open and fail-close. These modes determine the valve's behavior during an energy interruption and have a direct impact on the system's stability, safety, and efficiency.

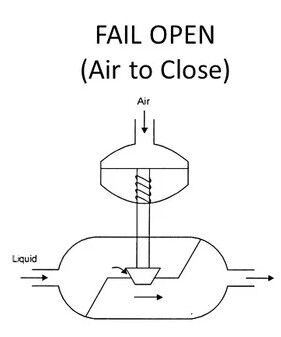

These valves automatically open fully in the event of an energy loss. They are suited for situations where maintaining fluid flow is necessary or where equipment damage needs to be prevented. Fail-open valves are also known as "fail-open valves" and are crucial in ensuring that the system continues to operate or prevents damage when the energy supply is interrupted.

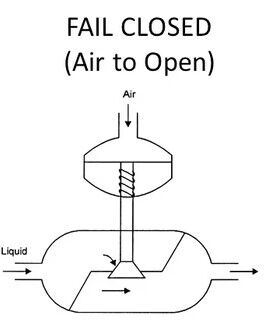

These valves automatically close fully in the event of an energy loss. They are ideal for situations where stopping the flow of fluid is critical to prevent potential hazards, such as leaks or equipment damage. Fail-close valves are commonly referred to as "fail-close valves" and are essential for safeguarding against the risks of fluid leakage or system malfunctions during an energy interruption.

When selecting the fail-open or fail-close mode for control valves, several factors must be considered to ensure system safety and efficiency. Below are specific criteria for various applications to help in choosing the most appropriate control valve type.

Ammonia Cooler Liquid Ammonia Control Valve: For protecting against damage to refrigeration systems caused by ammonia carryover, a fail-open valve is preferred. This valve closes automatically upon energy loss, preventing liquid ammonia leaks and thus safeguarding equipment and avoiding potential safety hazards.

Distillation Column Feed Valve: In cases of process accidents or system shutdowns, stopping the feed is essential to protect the system. A fail-open valve ensures automatic closure upon energy loss, preventing excessive material from entering the system. For reflux valves, a fail-close valve is recommended to avoid discharging unqualified products, reducing waste and resource loss.

Heating Material Control Valve:

High Outlet Temperature: Choose a fail-open valve to prevent decomposition, polymerization, or coking of materials, thereby protecting equipment and ensuring product quality.

Low Outlet Temperature: Opt for a fail-close valve to prevent crystallization or solidification of materials, ensuring normal system operation.

Cooling Water Control Valve: For systems using water as a cooling fluid, a fail-close valve is preferred. The valve remains fully open during an energy loss, ensuring continuous cooling water flow to prevent system overheating or equipment damage.

Control valve selection should consider the characteristics of the medium, as different mediums have varying behaviors and handling requirements that impact valve operation modes.

Distillation Column Bottom Discharge:

Crystallizable or Solidifying Medium: Choose a fail-close valve to prevent material from crystallizing or solidifying at the valve, avoiding equipment blockage and production interruption.

General Liquids: Opt for a fail-open valve to minimize energy consumption and avoid unnecessary material loss during an energy interruption.

Compressor:

Inlet and Bypass Control Valves: Select a fail-close valve to prevent pipe collapse and system overload. This mode ensures stable operation of the compressor during energy loss.

Discharge Pressure Control Vent Valve: A fail-close valve is recommended to avoid excessive internal pressure and reduce accident risk.

Boiler:

Steam Drum Steam Outlet Control Valve: Choose a fail-close valve to maintain system stability and prevent steam leakage or equipment damage.

Feed Water Control Valve:

Steam for Turbines: Opt for a fail-open valve to prevent steam carryover, ensuring normal turbine operation.

General Steam Applications: A fail-close valve is suitable to prevent explosions in the event of water loss in the boiler, ensuring system safety.

Product Quality: Ensure that the valve's response to signal pressure loss does not compromise product quality. For critical processes, selecting the appropriate fail-open or fail-close valve can prevent product defects or quality issues caused by improper valve states.

Material and Semi-Finished Product Waste: When selecting a control valve, consider minimizing raw material and semi-finished product waste. A fail-close valve can effectively prevent material leakage and losses during production.

In practical applications, choosing between fail-open and fail-close valves may involve certain challenges:

Load Variations: When dealing with significant load fluctuations, consider the flow characteristics to ensure accurate system regulation. Equal-percentage control valves are suitable for applications with large load changes, providing better flow control characteristics.

System Design: During the design of dosing systems, it is important to incorporate safety margins. Choosing the appropriate control valve mode can optimize system performance and prevent issues related to excessive or insufficient flow.

The choice between fail-open and fail-close control valves has a significant impact on the safety and efficiency of industrial processes. By carefully considering process safety, medium characteristics, production requirements, and practical challenges, you can select the most suitable control valve mode to ensure stable operations, enhance system efficiency, and optimize product quality. Proper valve selection not only improves system reliability but also reduces operational costs and safety risks.