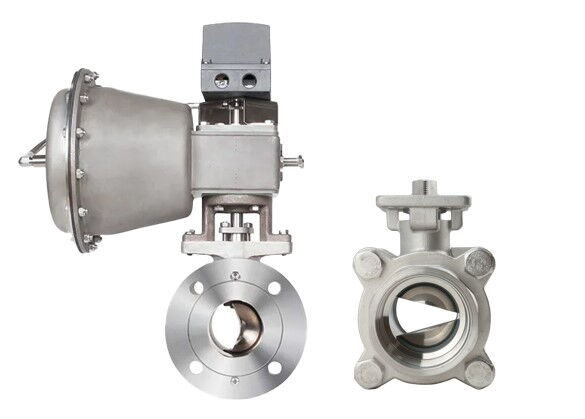

Sealing and Design Features of V-Port Ball Control Valves

On this page

The V-Port ball control valve is an advanced valve that combines precise flow control and efficient sealing in one design. It is widely used in industrial fluid control systems and applications with strict sealing requirements. Its innovative design allows the valve to achieve bubble-tight shutoff while offering excellent flow regulation, making it an essential control component in many complex processes. This article will explore the design features of V-Port ball control valves, analyzing how their precise ball design and efficient sealing performance achieve a Class VI bubble-tight seal.

One of the standout features of the V-Port ball control valve is its ability to provide a Class VI bubble-tight shutoff, ensuring zero leakage. This capability sets it apart in applications where sealing is critical, especially when precise flow control is needed without any fluid leakage. Compared to traditional standard ball valves with circular ports, the V-Port valve features a ball design that significantly improves sealing. The V-shaped ball and seat design maintains a tight seal as the valve approaches closure, preventing fluid from leaking. The V-shaped port design not only allows for precise flow control but also reduces friction with the seat, extending the valve's lifespan and enhancing its overall sealing performance.

The V-Port ball control valve is designed for exceptional flow control and fast response. It can precisely adjust flow rates, providing stable and repeatable control even between nearly closed and fully open positions. Compared to traditional shutoff valves, the V-Port valve is more compact and lightweight while offering a larger flow adjustment range. Its precision V-shaped cut gives the valve superior flow control characteristics, making it ideal for applications requiring rapid response and accurate control.

The fit between the V-shaped ball and the seat ensures a complete seal when the valve is closed, avoiding leakage issues common with conventional ball valves. The chamfered design of the ball reduces wear on the seat, enhancing durability and sealing performance. Furthermore, the V-Port valve has a wide adjustable range, with a minimum adjustment ratio of 200:1 and a maximum of over 800:1. This means it can precisely regulate flow to meet various process requirements. Within a typical 20%-80% control range, the V-Port valve provides consistent flow control, ensuring process stability.

The durability and efficiency of the V-Port ball control valve stem from its advanced sealing design. The ball and seat are made of precision-machined stainless steel and undergo mirror polishing, ensuring stable performance over time. The V-shaped ball design ensures that pressure drop occurs primarily at the edges of the V-shaped opening rather than the seat, reducing seat wear and improving durability. Additionally, the valve's sealing system employs a dynamic loading seal structure that automatically adjusts sealing pressure based on operating conditions, ensuring excellent sealing performance in all scenarios.

The chamfered edges of the V-shaped ball reduce wear on the seat and prolong the valve's service life. This design effectively minimizes leakage risks, even under high-pressure differential conditions, ensuring that no fluid leaks. The valve can withstand a pressure drop of up to 500 psi, making it ideal for applications that require high-pressure differential control.

The V-Port ball control valve is not only known for its excellent sealing performance and flow control abilities but also for its structure that enhances its versatility and ease of maintenance. Compared to traditional shutoff and segmented control valves, the V-Port valve is more compact, lighter, and cost-effective. Its unique design allows users to replace the seat online without disassembling the entire valve, reducing maintenance costs and minimizing downtime, thereby improving system reliability and efficiency.

Additionally, the V-Port valve is easy to install and maintain, with a ball and seat design that makes replacement straightforward. It is compatible with other equipment, enabling users to easily switch from a standard ball valve to a V-Port control valve by simply replacing the ball while keeping other components intact. Compared to competing valves, the V-Port ball control valve requires less maintenance, thanks to its standard end caps and seats, which allow seat replacements without full valve disassembly.

The V-Port ball control valve's design flexibility is another key feature. Depending on specific process requirements, the valve's ball and seat can be customized to meet customer needs. Manufacturers offer a variety of V-shaped and slotted ball ports to accommodate different fluid characteristics and flow control demands. The angle and port shape of the ball can be optimized for the application, allowing for specific control requirements to be met. By making slight adjustments to the ball design, the valve's Cv value and control characteristics can also be modified to suit different flow demands under varying process conditions.

The V-Port ball control valve stands out due to its innovative design features and exceptional performance, excelling in bubble-tight sealing, flow regulation accuracy, and efficiency. Its precise V-shaped ball design and efficient sealing technology ensure zero leakage in the most demanding conditions, offering a wide adjustment range and high repeatability. In terms of flow control precision and response speed, the V-Port valve offers clear advantages, particularly in applications requiring rapid adaptation to changing process conditions. With excellent sealing performance, easy maintenance, and flexible design options, the V-Port ball control valve is an ideal control element in many industrial fields, especially where high-precision flow control and sealing are required.