The Appliction of Diaphragm Control Valves in Process Control

A diaphragm control valve is a specialized form of shut-off valve, characterized by its unique structure and pivotal role in industrial and manufacturing processes. Utilizing a flexible diaphragm as its closing element, it effectively separates the internal cavity of the valve body from that of the valve cover, thereby controlling and regulating fluid flow. Beyond its primary function as a shut-off valve, the diaphragm control valve is also adept at facilitating flow switching and throttling.

1. Structure and Working Principle

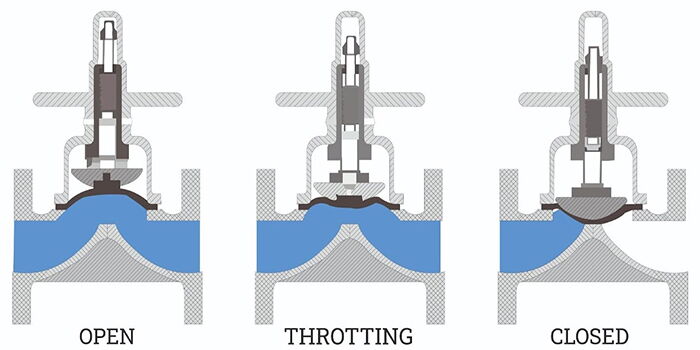

Comprising three main components – the valve body, diaphragm, and valve cover assembly – the diaphragm control valve boasts a straightforward structure that is both easy to maintain and operate. Its operational principle revolves around the movement of a compressible element, typically actuated by a valve stem, which raises and lowers the diaphragm to either allow or block passage. Designed to accommodate a diverse range of media, including corrosive, viscous, and inert substances, the diaphragm control valve finds extensive utility across industries such as biopharmaceuticals, food processing, and chemical engineering.

2. Material Selection and Temperature Range

The working temperature of a diaphragm control valve is typically dictated by the materials used for the diaphragm and valve body liner. Generally falling within the range of -50°C to 175°C, the valve's operational limits are determined by the properties of these materials. With the proliferation of synthetic rubbers and engineering plastics, coupled with an expanded selection of valve body liner materials, the diaphragm control valve finds increasing application in modern industrial settings.

3. Regulation and Hydraulic Balancing in Piping Networks

Beyond its role as a shut-off valve, the diaphragm control valve excels as a regulating valve. Its installation and calibration play a crucial role in achieving hydraulic balance within piping networks. Utilizing specialized intelligent instrumentation for calibration, the diaphragm control valve ensures stable operation and precise control of fluid flow within piping systems.

The diaphragm control valve's unique structure and multiple functions have positioned it as a cornerstone of industrial operations. Continual advancements in materials and technologies have broadened its application across various sectors, where it plays a pivotal role in enhancing energy efficiency and environmental sustainability. As industries evolve and demands shift, the diaphragm control valve will continue to play a vital role, evolving and refining to meet the challenges of modern manufacturing and production processes.