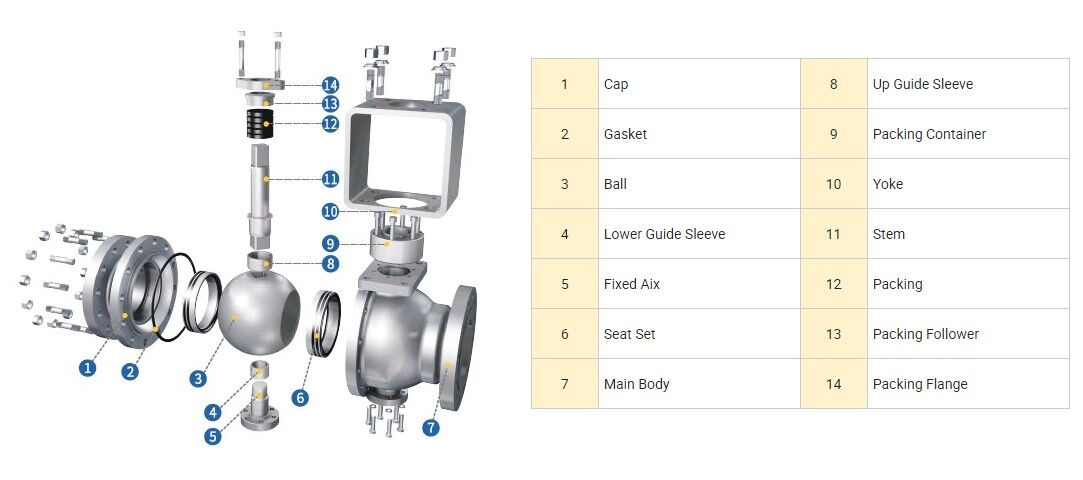

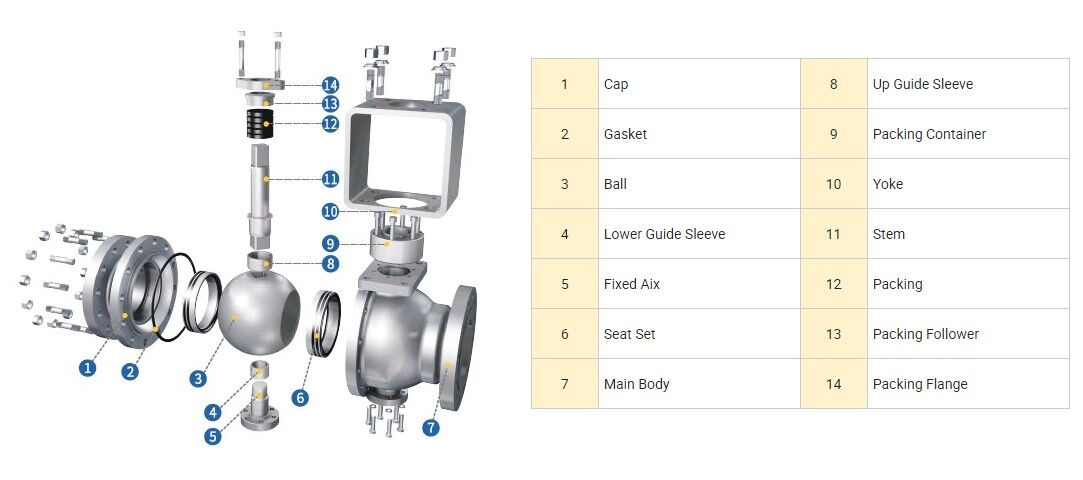

Product Name: Fixed Ball Control Valve

Type: Fixed Ball

Body Material: ASTM A216 WCB

Size: 10 Inch, DN250

Pressure: Class 150 LB, PN16

End Connection: Flanged

Actuation: Pneumatic Actuator

Flow Characteristics: Quick Open

Product Range

Standard: ASME, DIN, JIS, GB, etc

Body Material: Carbon Steel, Stainless Steel, Alloy Steel

Size Range: 2-12 Inch, DN50-DN300

Pressure Rating: PN10-PN160, Class 150-900 LB

Medium: Water, Oil, Gas, Acid

Working Temperature: -29°C to +560°C

End Connections: Flnaged, Welded, Threaded

Leakage Class: Fci 70-2 Class V, Class VI, Zero Leakage

Actuator Options: Spring Return or Double Acting Pneumatic Actuator

Travel: 90°

Air Pressure: 0.4-0.6 MPa

Optional Accessories: Volume Boosters, Position Transmitters, Limit Switches, Solenoid Valves, Handwheels, etc

Fixed Ball Control Valve Features

The fixed ball control valve, designed for high-pressure and large-diameter applications, offers two distinct configurations based on the placement of the valve seat sealing rings: one with the seat sealing in front of the ball and another with the seat sealing behind the ball. Here are the enhanced features of the fixed ball valve:

1. Advanced Seat Design: The valve seat is engineered with extensive experience to ensure a reliable seal, a low friction coefficient, and minimal operating torque. A variety of seat materials are utilized to cater to different operational needs.

2. Error-Free Operation Handle: The flat head stem is employed to prevent misalignment in the handle's connection, ensuring that the state of the handle accurately reflects the valve's position.

3. Locking Mechanism: To prevent accidental operation, the valve features locking holes when fully open, ensuring that the valve remains in the correct position and reducing the risk of misoperation.

4. Stem Anti-Flying Feature: The stem is secured to prevent it from being forced out by pressure, and in the event of a fire, metal-to-metal contact can be established to ensure the stem's seal integrity.

5. Anti-Static Performance: Springs are installed between the ball, stem, and valve body to dissipate static electricity generated during the switching process, enhancing safety.

6. Fire-Safe Construction: The design of various components, including the ball and valve body, middle flange, stem, and valve body, meets stringent fire resistance standards, complying with API 6FA and API 607 requirements.