Split Range Control Systems: Boosting Control Valve Efficiency

On this page

Split range control systems are one of the essential technologies in modern industrial automation control, widely used in industries such as oil, chemical, and power generation. Through efficient signal decomposition and regulation, these systems can precisely control multiple control valves, optimizing the management of complex process operations. This article will delve into the working principles, types, advantages, and the significance of control valves in split range control systems.

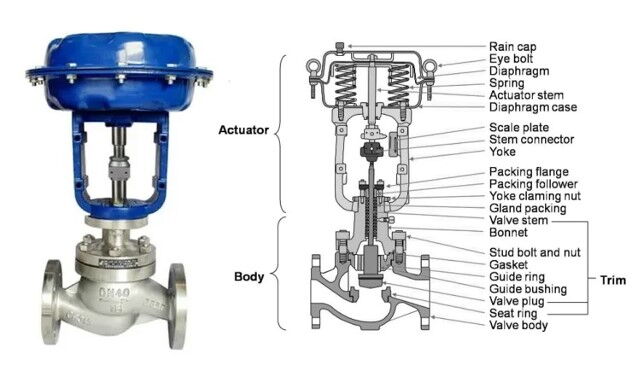

The core of split range control systems lies in utilizing simulated instruments and controllers to decompose the output signals of the controller into different range segments with the help of valve positioners. Each range segment's signal can independently control a regulating control valve, enabling the controller to manage two or more control valves simultaneously, significantly improving the system's control performance.

In this process, valve positioners play a critical role by accurately transmitting the controller's signals to the control valves. Through precise signal decomposition, the control system can achieve fine adjustments of fluid flow, pressure, and temperature, ensuring the stability and safety of the process.

Split range control systems are mainly divided into two types: hard split range and soft split range.

In hard split range control systems, the role of valve positioners is decisive. They decompose the output signals from the controller, achieving full range adjustments of the regulating control valves. The advantages of hard split range control include simple structure and fast response, making them suitable for applications requiring high control precision. However, this model has some limitations, such as a failure in one control valve potentially leading to the entire system's failure, complicating maintenance, and increasing the risk of human error.

In contrast, soft split range control systems are more flexible, utilizing software systems to manage the forward and reverse actions of the control valves. It operates using two independent loops for the control valves, ensuring no interference between the loops. Users can set up operating programs based on process requirements or the adjustable range of the control valves, effectively improving control flexibility. This approach is suitable for complex processes requiring high operational frequency and rapid response.

The advantages of split range control systems primarily manifest in the following aspects.

Split range control systems can flexibly select valve types under different operating conditions. For example, in a steam pressure reduction system, parallel use of different-sized control valves allows for larger valves during higher flow rates and smaller valves during lower flow rates. This configuration significantly enhances the system's regulation capability, enabling control valves to operate effectively across a broader flow range.

Split range control allows multiple smaller final control elements, specifically control valves, to act collectively on the regulation of process variables, achieving finer control. For complex production processes, split range control can manage various media simultaneously, such as the coordinated control of pressure relief and nitrogen fill control valves for tanks, ensuring the system's safety and stability.

In certain chemical reactions, such as exothermic reactions, the system may need to adjust control strategies based on changes in reaction stages. Initially, hot water may be required to rapidly increase temperature, while cold water is needed later to control temperature. This stage-based split range control scheme can ensure the stability and safety of the reaction process through appropriate adjustments of control valves.

The practical applications of split range control systems are extensive, primarily including the following aspects.

Split range control is particularly suitable for processes that require multiple control methods working together to achieve the same control goal. When a process variable requires multiple control strategies, split range control is typically employed. For example, in temperature control, when the temperature falls below the set point, the cold water control valve is closed first, and only after it is fully closed is the hot water control valve opened; conversely, when the temperature exceeds the set point, the hot water control valve is closed first, followed by the opening of the cold water control valve to maintain a constant system temperature.

Although split range control systems are fundamentally simple control systems, PID tuning must consider the characteristics of both control channels. It is essential to ensure that the overall performance of the control loop remains acceptable when using different final control elements, such as control valves. A common error in selecting split points is that many on-site practices set the split point at 50%. However, if the gains of the two final control elements for the process variable are inconsistent, appropriate split point settings should be implemented to maintain consistent characteristics on the controlled object, allowing a single set of control parameters to achieve uniform control performance throughout the range.

Split range control systems enhance the flexibility and efficiency of industrial automation control through adaptable signal decomposition and coordinated control methods involving multiple control valves. Their advantages are even more pronounced in complex environments where multiple control approaches target the same control goal. With careful design and implementation, split range control can significantly improve the quality and speed of control in production processes, particularly through precise fluid regulation via well-chosen and applied control valves, ensuring the safety and stability of industrial processes. As industrial automation technology continues to advance, split range control systems will play an increasingly important role, providing more efficient and precise solutions for production management across various industries.