Understand the Role of Control Valves in Control Loop

On this page

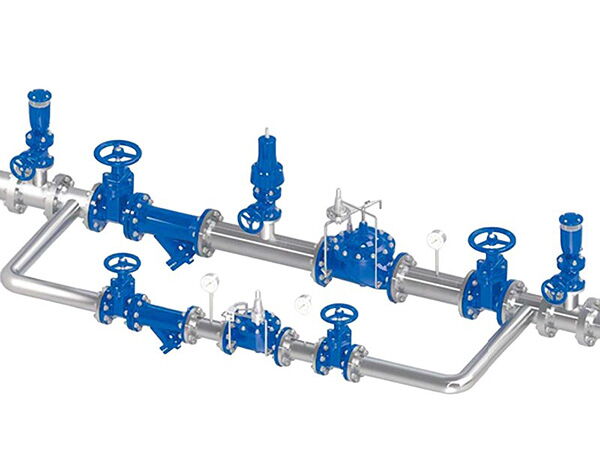

In modern industrial processes, control valves are core components for achieving precise control. To ensure the effectiveness of control valves in control loops, it is crucial to understand both the construction of control loops and the static and dynamic characteristics of control valves. A control loop consists of three main components: the sensing element, the control instrument, and the final control element. Each component's function and interrelationships are decisive for the efficiency and accuracy of the control valve. Understanding these components and their characteristics is essential for optimizing the overall performance of the control system.

To grasp the role of control valves in a control loop, we need to examine the three main components of the control loop. The function and interrelationships of each component determine the efficiency and accuracy of the control valve.

The sensing element, usually a transmitter, measures the process parameters being controlled in real-time. These parameters can include pressure, level, temperature, etc. The transmitter's function is to convert the actual measurement into an electrical or pneumatic signal and transmit it to the control instrument. The accuracy and response speed of the transmitter directly impact the overall performance of the control loop, as it provides the real-time data required for the control system's decision-making.

The control instrument, also known as the controller, processes the signals received from the transmitter. Its primary task is to compare the actual process parameters with the preset target values and calculate the deviation between them. The controller generates a correction signal based on this deviation, which is then sent to the final control element—the control valve. The performance of the controller, including its accuracy, stability, and response time, collectively determines the effectiveness of the control system.

As the final control element, the control valve adjusts the fluid flow based on the correction signal from the controller, thereby achieving precise control of the process parameters. Control valves can operate pneumatically or electrically:

Pneumatic Control Valves: In pneumatic systems, the controller's pneumatic signal drives a spring-diaphragm or piston actuator to control the valve's opening and closing. Pneumatic systems require a stable supply of compressed air, which must be dried, purified, and filtered to ensure system reliability and performance.

Electric Control Valves: In electric systems, the controller uses an electrical signal to drive an electric actuator, adjusting the valve's position. These systems typically require a stable power supply, and electric actuators usually offer higher control accuracy.

Control valves play a critical role in control systems, and their performance directly affects the effectiveness of the entire control loop. The performance of control valves can be assessed from static and dynamic perspectives. Understanding these characteristics helps optimize the performance of the control system, ensuring the stability and accuracy of process parameters.

Static characteristics describe the flow behavior of a control valve in a stable state and include several aspects.

Flow Characteristics: This refers to the valve's flow capacity at different openings. Common flow characteristic curves include linear, equal percentage, and quick opening. These characteristics determine how the valve affects fluid flow at various openings.

Valve Size and Structure: The size and structure of the valve, including the design of the valve plug and seat, significantly affect the static characteristics. Factors such as flow capacity, pressure loss, and control accuracy are closely related to the valve's size and structure.

Actuator: The type (pneumatic or electric) and configuration (pneumatic diaphragm or electric actuator) of the actuator also impact the static characteristics. The precision and response speed of the actuator determine the accuracy of the valve's position control.

Pressure Upstream and Downstream of the Valve: The flow characteristics of the valve are influenced by the pressure upstream and downstream. Variations in pressure differentials can cause fluctuations in flow characteristics, so actual operating conditions must be considered when selecting a control valve.

Fluid Properties: The properties of the fluid, such as viscosity and density, also affect the valve's flow characteristics. Different fluid properties can alter the flow characteristic curves, so it is essential to select a valve suited to the specific application.

Dynamic characteristics reflect how quickly and stably a control valve responds to changes in control signals and include several aspects.

This is the time it takes for the control valve to respond to a change in the control signal. It determines how quickly the valve adjusts after receiving a control signal. A long response time can lead to delays in the control system, affecting overall performance.

Hysteresis refers to the time delay experienced during actual valve operation. It can slow down the control system's response and impact process control stability, especially in systems with rapid changes like flow control.

Stability refers to whether the control valve maintains a steady operating state when responding to control signals. A valve with good dynamic characteristics adjusts its position quickly and steadily, avoiding instability due to over-adjustment or oscillation.

Dynamic characteristics are also influenced by the combination of the actuator and valve positioner. The performance of the actuator and the accuracy and adjustment capability of the valve positioner jointly determine the valve's dynamic response. For high-precision systems, selecting high-performance actuators and positioners is crucial.

In practice, the dynamic characteristics of control valves can be improved through system optimization. Adjusting controller parameters, control algorithms, and overall system design can impact the dynamic performance of the control valve.

Control valves are vital in control systems, with their performance directly affecting the stability and accuracy of process parameters. By understanding the three main components of the control loop—sensing element, control instrument, and final control element—we gain insight into the control valve's role in the system. Additionally, both the static and dynamic characteristics of control valves have profound effects on the control system's performance. Static characteristics determine the flow capacity in a stable state, while dynamic characteristics affect the valve's response speed and stability to control signal changes. Considering these factors helps in selecting and optimizing control valves suitable for specific applications, thereby enhancing the overall performance and reliability of the control system.